111188822

滚动文字

滚动文字

滚动文字

Packaging Materials and Mechanical Solutions

Manufacturing high strength PET plastic steel belt, machine wrapping film, hand wrapping film, a variety of senior PP packing belt, tape, packaging machinery.

LEARN MORE +

Scroll loading

Packaging Materials and Mechanical Solutions

Manufacturing high strength PET plastic steel belt, machine wrapping film, hand wrapping film, a variety of senior PP packing belt, tape, packaging machinery.

了解更多 +

Scroll loading

About Hongda Packaging

About HONGDA

Found in 2002, Zhejiang Hongda Packaging Technology Co. Ltd.(The original Haiyan Hongda plastic packaging factory) is known as “the land of fish and rice “, located at Haiyan, Zhejiang, next to Hangzhou Bay Bridge, the traffic and logistics is convenient.

Hongda has developed into a investigation, production, sale and the after service of packing materials and packing machinery. Manufacturing high strength PET plastic steel belt, machine wrapping film, hand wrapping film, a variety of senior PP packing belt, tape, packaging machinery. Products involved in energy, metals, manufacturing, decoration and other industries.

Establishment of original factory

Factory floor area

Company employees

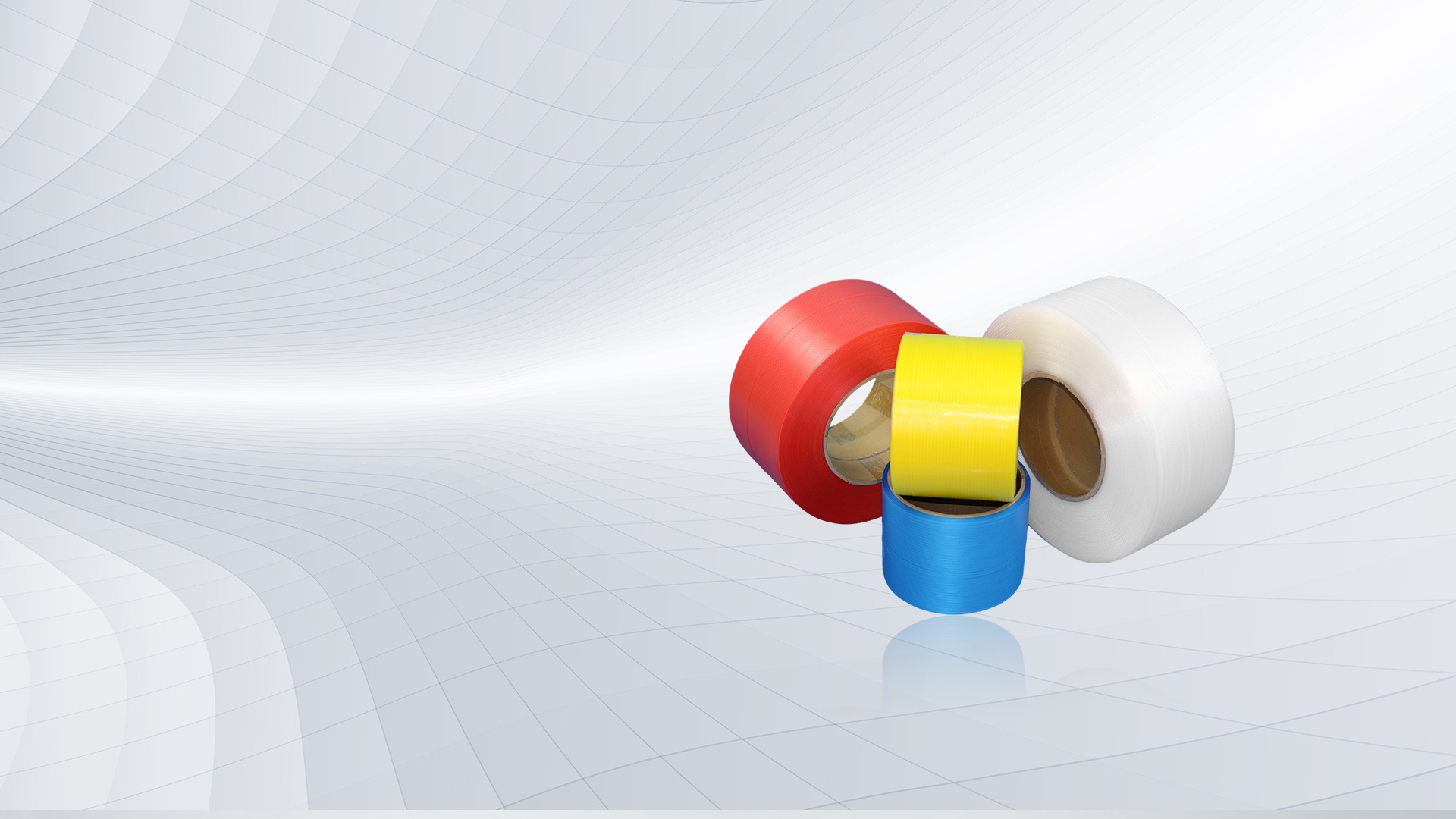

Strapping

Manufacturing high strength PET plastic steel belt, machine wrapping film, hand wrapping film, a variety of senior PP packing belt, tape, packaging machinery.

LEARN MORE +PET Belt

Manufacturing high strength PET plastic steel belt, machine wrapping film, hand wrapping film, a variety of senior PP packing belt, tape, packaging machinery.

LEARN MORE +Stretch Film

Manufacturing high strength PET plastic steel belt, machine wrapping film, hand wrapping film, a variety of senior PP packing belt, tape, packaging machinery.

LEARN MORE +Environmental Protection Tape

Manufacturing high strength PET plastic steel belt, machine wrapping film, hand wrapping film, a variety of senior PP packing belt, tape, packaging machinery.

LEARN MORE +Packing Machine

Manufacturing high strength PET plastic steel belt, machine wrapping film, hand wrapping film, a variety of senior PP packing belt, tape, packaging machinery.

LEARN MORE +DEVELOPMENT

Sustainable Development

DEVELOPMENT

Wide variety, guaranteed quality

Focused on the plastic packaging industry for 20 years, we offer advanced equipment and a comprehensive product range—everything from shrink films and stretch wraps to strapping tapes, providing tailored protection for your products.

Rigorous quality inspection, with checks at every level

We carefully select premium raw materials and maintain rigorous quality control throughout every step of the process, ensuring top-notch product quality. Additionally, we utilize advanced, domestically-produced equipment and have incorporated cutting-edge German manufacturing technology to deliver even higher-quality products.

Tailor-made, reducing costs

Based on customer needs, we offer cost-effective, versatile, and enhanced product options with superior value for money. We’ve already provided high-quality packaging materials to over a thousand businesses, earning us the trust and confidence of our clients.

Factory direct sales, timely delivery

Daily production reaches over 50 tons, with a substantial stock of 800 tons for our standard products—ensuring ample supply to meet bulk customization and procurement needs. For standard packaged products, orders placed by the end of the day are shipped out the same day. Customized products are delivered swiftly within 3 to 5 days.

NEWS

News and Information

Information

Various forms of use of stretch film

1. Sealed packaging This type of packaging is similar to shrink wrap, where the film wraps the tray around the tray, and then two heat grippers heat seal the film at both ends together. This is the earliest form of wrapping film, and more packaging forms have been developed from this 2. Full width packaging This kind of packaging requires that the film width is enough to cover the tray, and the shape of the tray is regular, so it is suitable for use with a film thickness of 17-35μm 3. Manual packaging This kind of packaging is the simplest kind of wrapping film packaging, the film is loaded on a rack or by hand, and the film is rotated by the tray or the film is rotated around the tray. Mainly used for repackaging after the packaged pallet is damaged, and ordinary pallet packaging. This kind of packaging speed is slow, and the suitable film thickness is 15-20 μm; 4. Stretch film wrapping machine packaging This is one of the most common and widespread forms of mechanical packaging. The tray rotates or the film rotates around the tray. The film is fixed on the support and can move up and down. This packing capacity is very large, about 15 to 18 trays per hour. The suitable film thickness is about 15-25μm; 5. Horizontal mechanical packaging Different from other packaging, the film revolves around the item, which is suitable for the packaging of long goods, such as carpets, boards, fiberboards, special-shaped materials, etc.; 6. Packaging of paper tube It's one of the newest uses for stretch wrap, and it's better than the old-fashioned paper tube wraps. The suitable film thickness is 30~120μm; 7. Packaging of small items This is the latest packaging form of wrapping film, which can not only reduce material consumption, but also reduce the storage space of pallets. In foreign countries, this kind of packaging was first introduced in 1984. Just one year later, many such packaging appeared on the market. This packaging format has huge potential. Suitable for film thickness of 15 ~ 30μm; 8. Packaging of pipes and cables This is an example of the application of stretch film in a special field. The packaging equipment is installed at the end of the production line, and the fully automatic stretch film can not only replace the tape to bind the material, but also play a protective role. The applicable thickness is 15 to 30 μm. 9. Stretch form of pallet mechanism packaging The packaging of stretch film must be stretched, and the stretching forms of pallet mechanical packaging include direct stretching and pre-stretching. There are two types of pre-stretching, one is roller pre-stretching and the other is electric stretching. The above are the various forms of use of the wrapping film that Xiaobian shared with you today. If you want to know more about the wrapping film, please call for consultation! !

28

2021-12

How to maintain and maintain the baler from time to time

The four points that the baler needs to be maintained: 1. Adjust the bundling tightness of the mechanical baling material of Bohong baling belt. Open the table top, loosen the hexagon socket set screw on the top of Daluomu A by hand, and turn it clockwise to tighten, and vice versa. for pine. After the binding force is moderate, tighten the hexagon socket set screw. 2. Adjustment of belt width and joint opening. When the belt width is uneven or the belt of another width is replaced, the left and right belt insertion slots must be adjusted. If the slot is too narrow, the belt insertion will be difficult; if it is too wide, the belt will be joined after baling There will be misalignment. Generally, the width of the slot should be about 0.5-1 mm wider than the width of the belt. 3. Adjust the temperature of the ironing head of the baler

22

2018-12

When using the baler, you need to pay attention to those problems

Steel rolling mills, recycling and processing industries, non-ferrous and ferrous metal smelting industries, and renewable utilization industries Y81 series hydraulic metal balers can pack various metal scraps. Extrusion of qualified charge of various shapes such as cuboid, octagon, cylinder, etc. can not only reduce the cost of transportation and smelting, but also increase the speed of charging. There are shadows of balers in these areas. So what should I pay attention to when using the machine? 1. Please confirm the power supply used by the machine, and do not insert the wrong power supply. This machine adopts a three-phase four-wire system. The flower wire is the grounding neutral wire for leakage protection. 2. Do not touch the heating plate directly with your hands. 3. Do not stick oil on the surface of the belt roller.

22

2018-12

Cooperate

Partner Clients

Cooperative clients

Jiahua Energy

Follett Group

JKS

Jiaxibela

Qisheng Technology

Hesheng Silicon Industry

Yanjing Beer

Contact

Contact us

Contact US

Zhejiang Hongda Packaging Technology Co., Ltd.

Address: No. 713 Qiujia Road, Huangqiao Industrial Zone, Yucheng Town, Haiyan County, Jiaxing City, Zhejiang Province